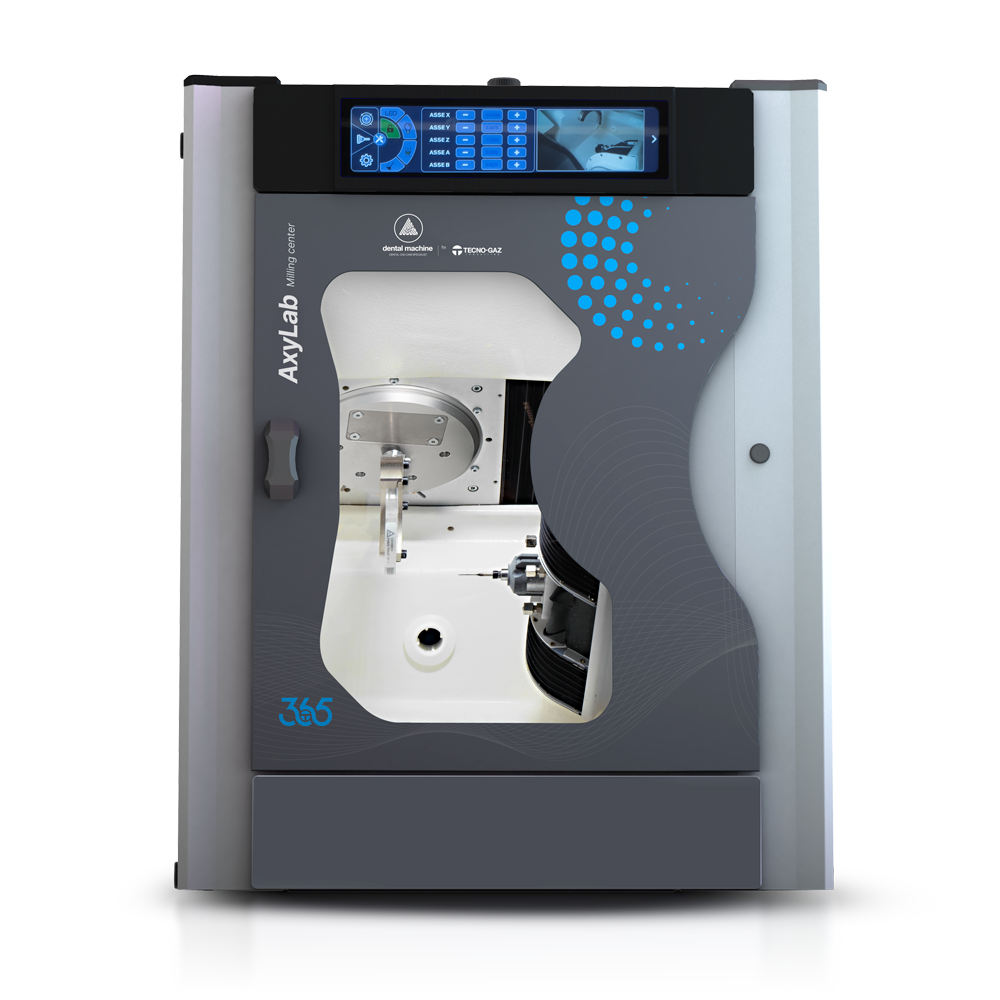

Compact 5-axis milling machine

AxyLab

Choose AxyLab and you are at the centre of a digital ecosystem designed especially for you.

The first true “Compact” model from Dental Machine without sacrificing the performance of the more complex milling machines in our range.

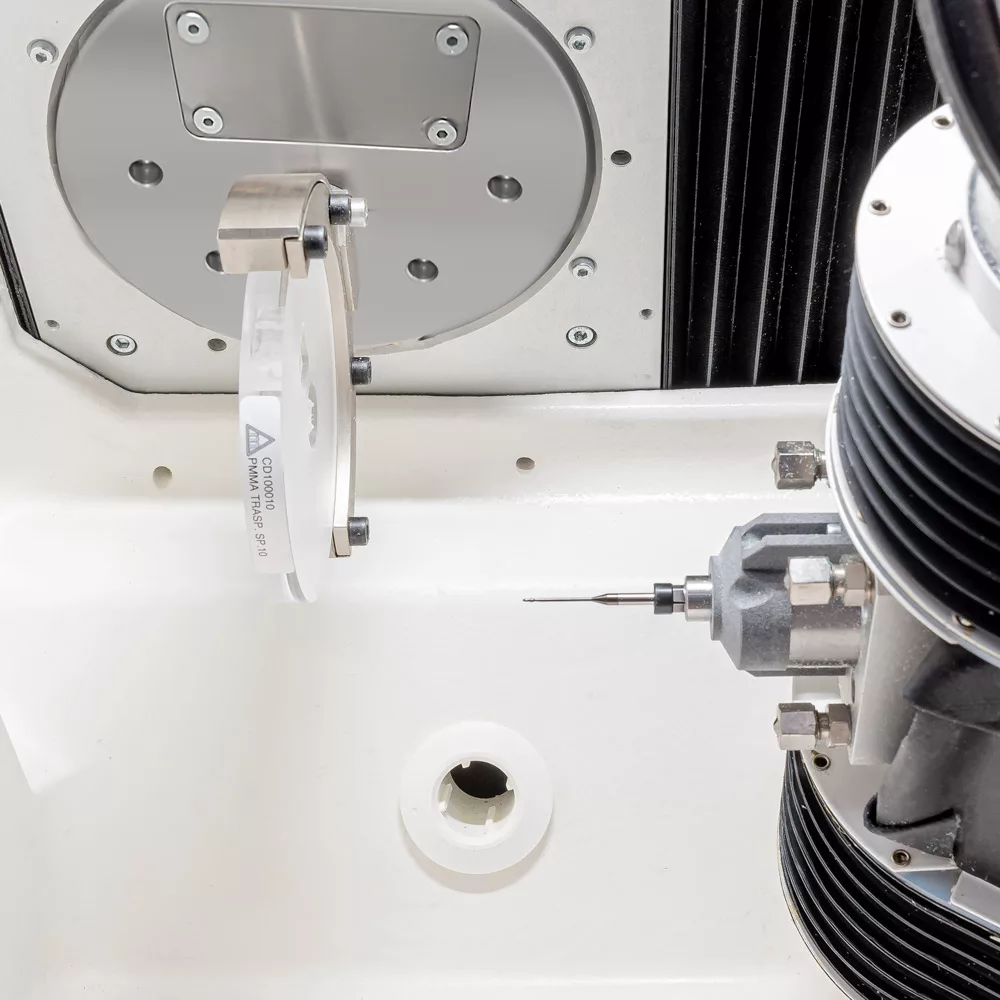

The Smart Wet lubrication system is essential for machining ceramic glass and composites and the milling of individual titanium abutments using Premilled blanks.

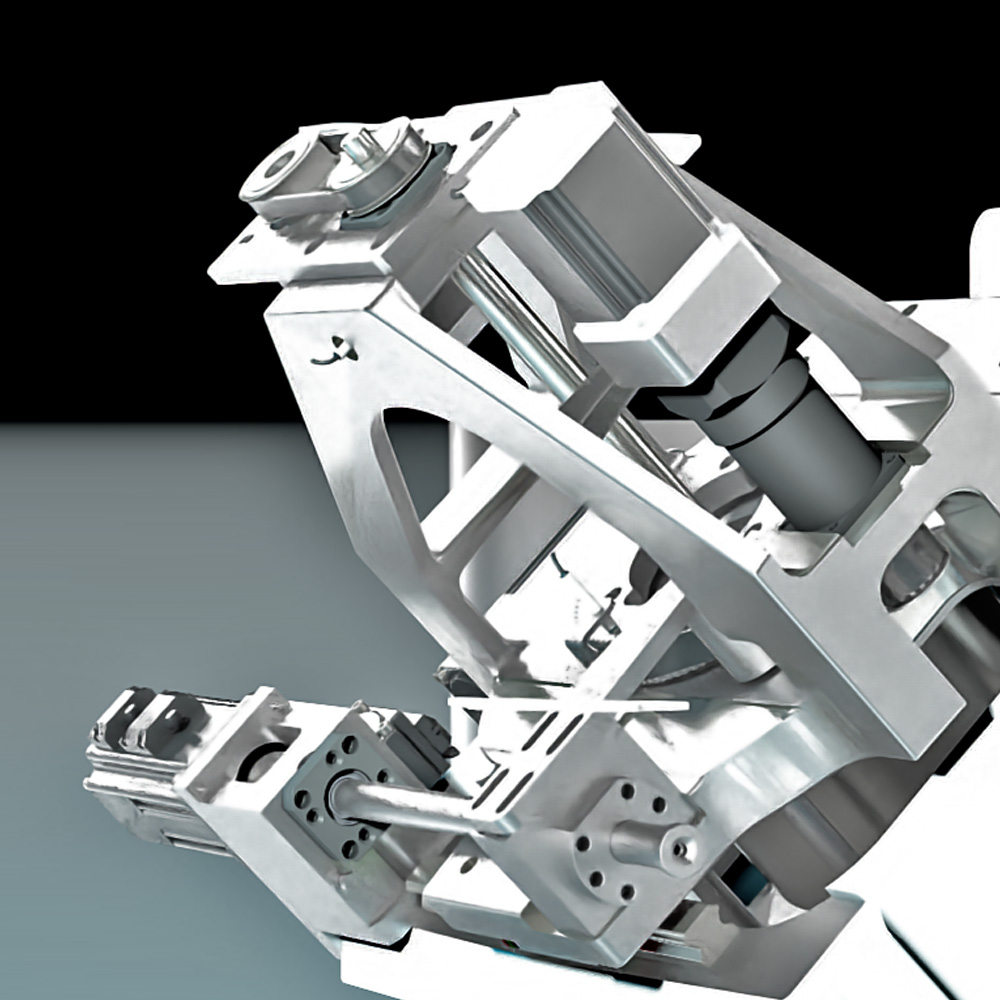

5 continuous axes

Dry and wet milling

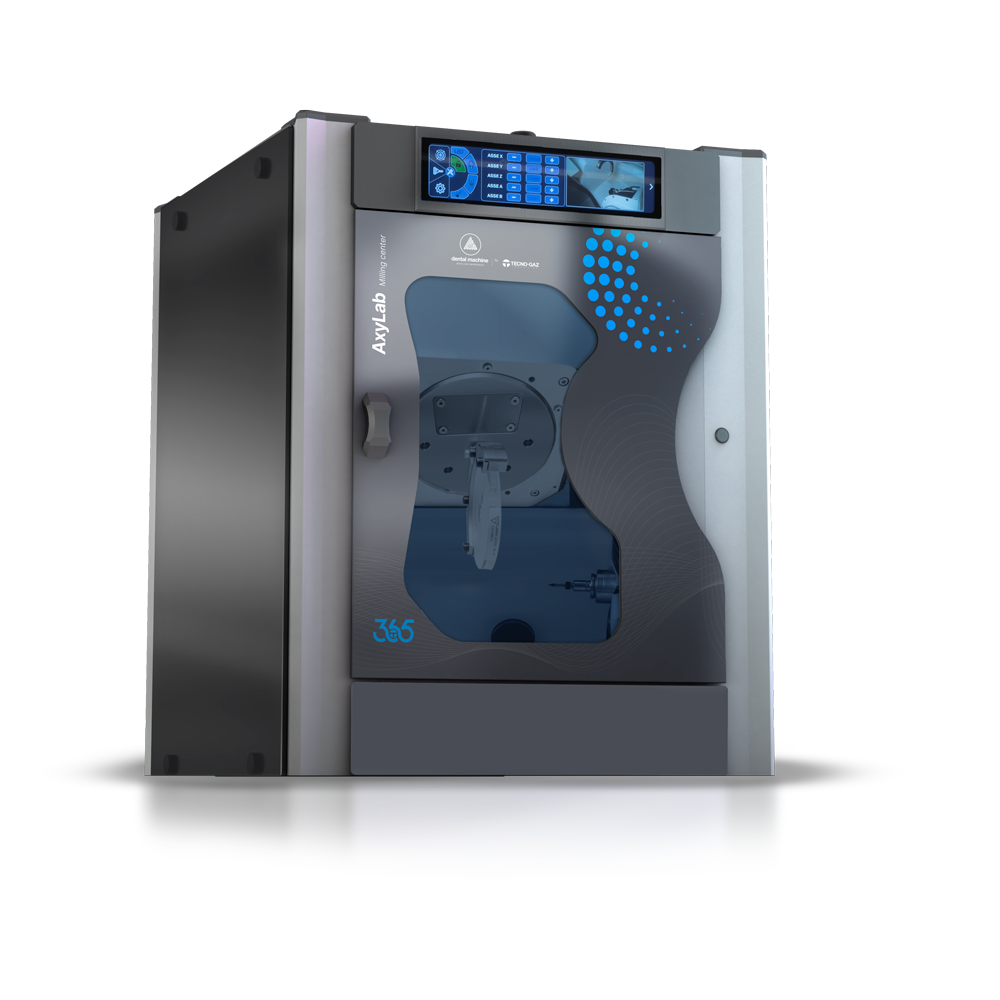

11” touchscreen monitor

Built-in camera

Built-in compressor

- Precision

- Repeatability

- Machinable materials

Universal milling machine for the dental sector.

Winning features

AxyLab was created to meet the needs of those entering the digital world, but do not want compromises and demand the performance for which high-end Dental Machine systems are famous.

High-frequency spindle up to 550 W power

High frequency piloted spindle, 550 W and 60,000 rpm for 3 mm tool shank.

Built for hard work…

with soft materials

Sturdy steel construction for maximum stability (150 kg). Less vibrations, longer-lasting mechanical components.

Its compact size means it can be installed in any room in the laboratory and can be placed in any work environment.

All the control you need

Streamlined strategies for 5-axis continuous milling on all materials.

High-end mechanical components

Destined to become a leader

Ideal for zirconia milling

Thanks to its design logic, AxyLab revolutionises the way Zirconia is milled.

5 continuous axes to fully exploit the milling machine’s potential in terms of execution speeds reduced by 30% and the creation of very thin cervical edges while minimising operator time when finishing the prosthesis.

Enter the Premilled world

Optimised for milling premilled blanks

In the world of dental CAD/CAM, pre-milled is a titanium or cobalt-chrome block equipped with a pre-machined engagement from which to obtain a customized abutment by milling. It allows to combine industrial precision in the engagement with the versatility of digital dental technology in the creation of the shape of the abutment.

Machinable material

Machinable material

Machinable material

Machinable material

Machinable material

Machinable material

Download

Download the relevant Digital Workflow brochure.

Download the Digital Workflow brochure

Superior quality and instantly operative

Reasons for choosing AxyLab

The linear axes are moved by preloaded ground ballscrews, driven directly by high-frequency motors to ensure precision and durability. Continuous lubricated significantly reduces maintenance.

It is essential today for a workshop that wants to enter the world of milling to start with 5-axis technology. The fifth axis makes it possible to replicate undercut zones and manage machining operations that do not have a parallel axis. (Practically 90% of daily machining operations). 5 axes means potentially being able to mill any job.