Chairside milling machine

AxyMat

Milling machine designed to meet the requirements of “digitalised” dental practices.

5 axes, for wet and dry milling of all materials*.

High-quality components allow restorations with a high level of finish, thus reducing manual adjustment time.

The design and production flow is fast and integrated thanks to the implementation of specific, state-of-the-art software.

*Titanium only in “pre-milled” form.

5 continuous axes

Dry and wet milling

11” touchscreen monitor

Built-in camera

Built-in compressor

- Precision

- Repeatability

- Machinable materials

Chairside milling machine.

Winning features

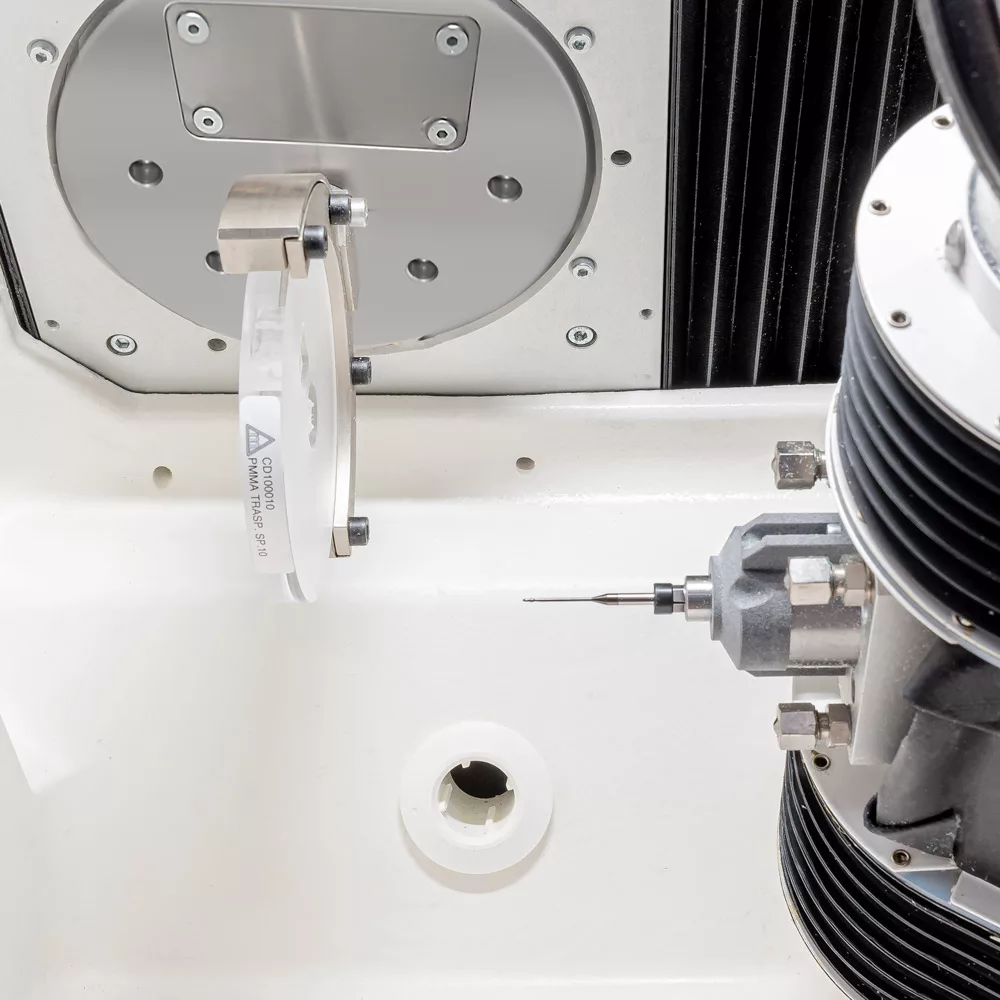

High-frequency spindle up to 550 W power

High frequency piloted spindle, 550 W and 60,000 rpm for 3 mm tool shank.

Built for hard work…

with soft materials

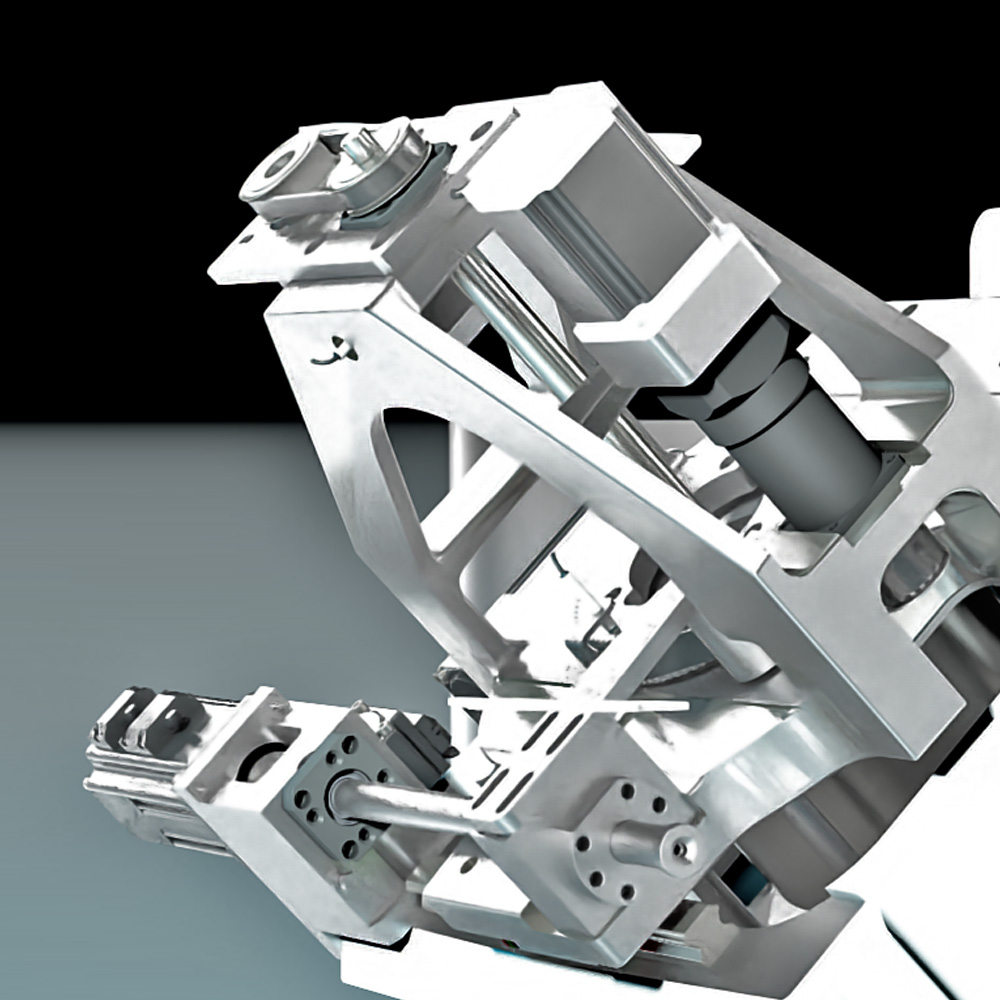

Solid steel structure for maximum stability (140 kg). Reduction of vibrations, longer life of mechanical components.

Its compact dimensions mean it can be installed in any room in the studio.

All the control you need

Streamlined strategies for 5-axis continuous milling on all materials.

High-end mechanical components

Destined to become a leader

Ideal for zirconia milling

Thanks to its design logic, AxyLab revolutionises the way Zirconia is milled.

5 continuous axes to fully exploit the milling machine’s potential in terms of execution speeds reduced by 30% and the creation of very thin cervical edges while minimising operator time when finishing the prosthesis.

Enter the Premilled world

Optimised for milling premilled blanks

In the world of dental CAD/CAM, a pre-milled abutment is a block of titanium or chrome-cobalt with a pre-milled implant connection from which a customised abutment can be milled. It allows industrial precision in the implant connection to be combined with the versatility of digital dental technology in the production of the abutment shape.

Machinable material

Machinable material

Machinable material

Machinable material

Machinable material

Machinable material

Download

Download the relevant Digital Workflow brochure.

Download the Digital Workflow brochure

Superior quality and instantly operative

Reasons to choose AxyMat

The linear axes are moved by preloaded ground ballscrews, directly controlled by high-frequency motors to ensure precision and durability. Continuously lubricated, thus significantly reducing maintenance.

It is essential today for a practice that wants to extend its treatment range to start with 5-axis technology. The fifth axis makes it possible to replicate undercut areas and manage machining that does not have a parallel axis. (Practically 90% of daily machining). 5 axes means potentially being able to mill any workpiece.